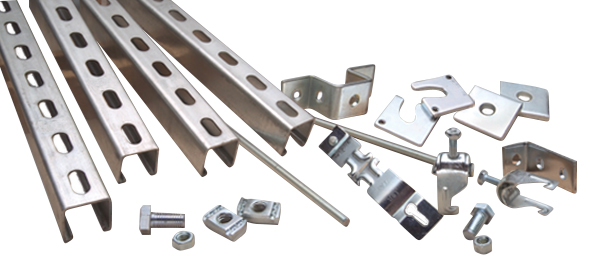

Superstrut®

Superstrut®, with a full complement of fittings, hardware and accessories to complete any metal framing job, is the only system of its kind to provide multiple finishes for total corrosion protection.

White Papers:

Salt Water Testing for Galvanized Metal Strut

Features

GoldGalv: All surfaces are protected with a trivalent chromium finish applied over zinc, creating a chemically bonded non-porous barrier. GoldGalv finishes are applied after cutting and punching which protects all surfaces of the finished product.

SilverGalv: All surfaces are electro-plated with 0.5 mils of zinc after cutting and punching, providing a durable, corrosion resistant product. SilverGalv corrosion resistance is between that of Gold Galv, and Pre-Galvanized products.

Hot Dipped Galvanized: The material is zinc coated after fabrication, providing total product protection on all surfaces.

Pre-Galvanized: A zinc coating is applied by hot dipping the steel at the mill prior to fabrication.

Superstrut introduces two new products:

3 sided half-slot channel:

Half-slots on all three sides of the channel increase flexibility and adaptability during installation. This also enables users to make side-to-side connections and attach various accessories to all sides of the strut.

Wide half-slot channel:

Contractors no longer need to drill holes in strut to accommodate 5⁄8″ threaded rod. The new Superstrut wide half-slot channel offers a time-saving alternative.

SuperMag Product Information

Document Downloads: